Tel: +86-15381707657

Email: cherryzhuang@editextile.com

Tel: +86-15381707657

Email: cherryzhuang@editextile.com

Tel: +86-15381707657

Email: cherryzhuang@editextile.com

---------Key Attributes

·Industry-Specific Attributes

|

Material |

100% Polyester |

|

Technics |

Knitted |

|

Unpick and Wash |

Washable |

·Other Attributes

|

Place of Origin |

Zhejiang, CHINA |

|

Brand Name |

EDITEX |

|

Feature |

Anti- Pill/ Anti-Bacteria/ Folded |

|

Shape |

Rectangular |

|

Is_Customized |

YES |

|

Weight |

1KG |

|

Product Name |

Flannel Fleece Fabric |

|

Usage |

Pajama/ Blanket/ Bathrobe |

|

MOQ |

1000kg |

|

Age Group |

All-Age |

·Packing and Delivery

|

Selling Units |

Single item |

|

Selling package size |

190x25x50 centimeter |

|

Selling gross weight |

40KG |

·Lead Time

|

Quantity(kg) |

1000-2500 |

2500-4000 |

>4000 |

|

Lead Time |

18 |

30 |

To be negotiated |

---------Samples

|

Maximum Order Quantity |

0.1kg |

|

Sample Price |

$0.1 |

---------Overview

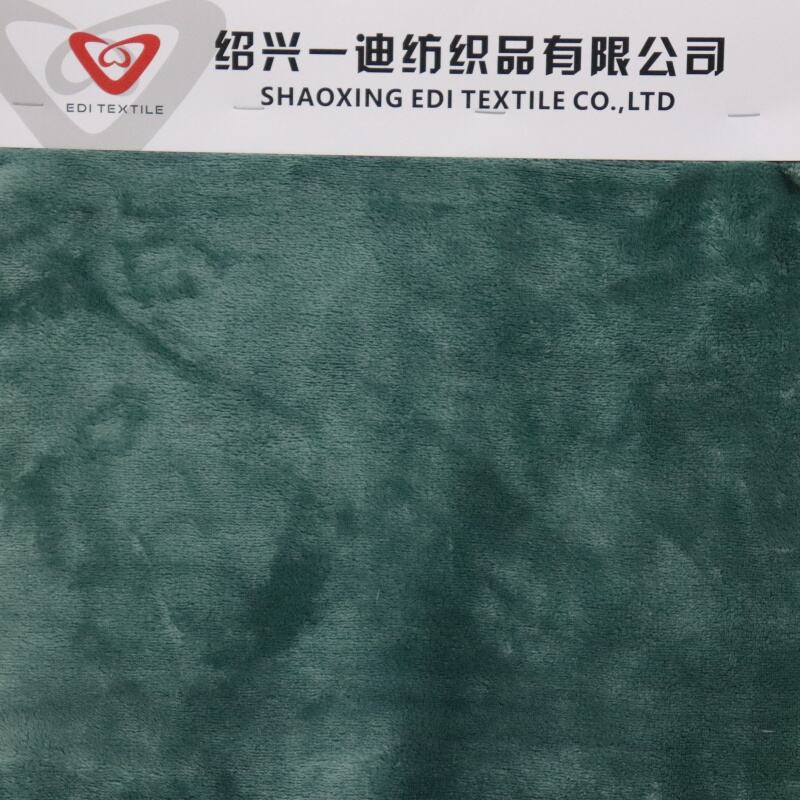

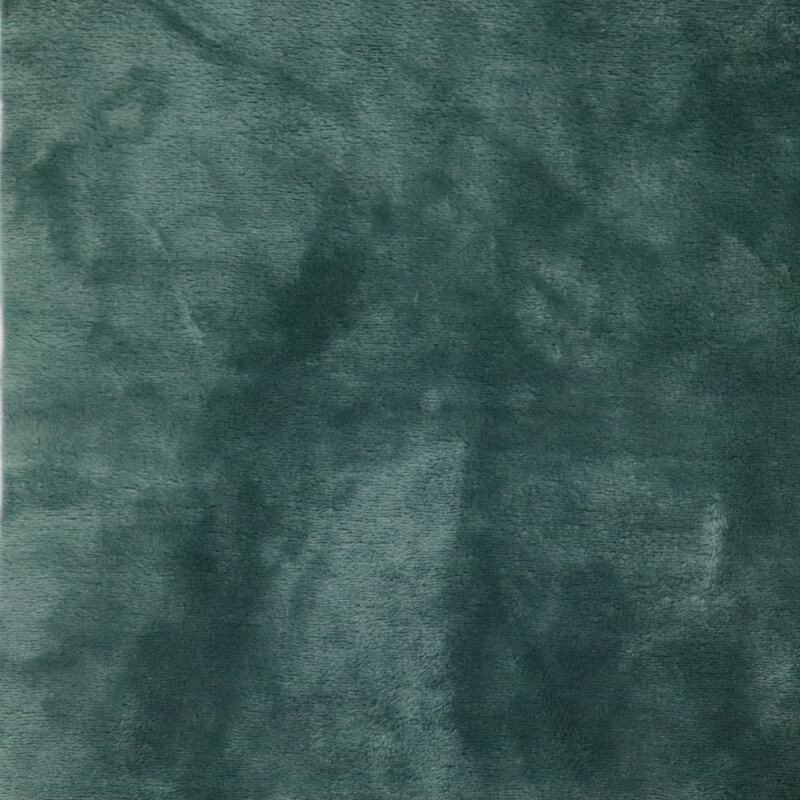

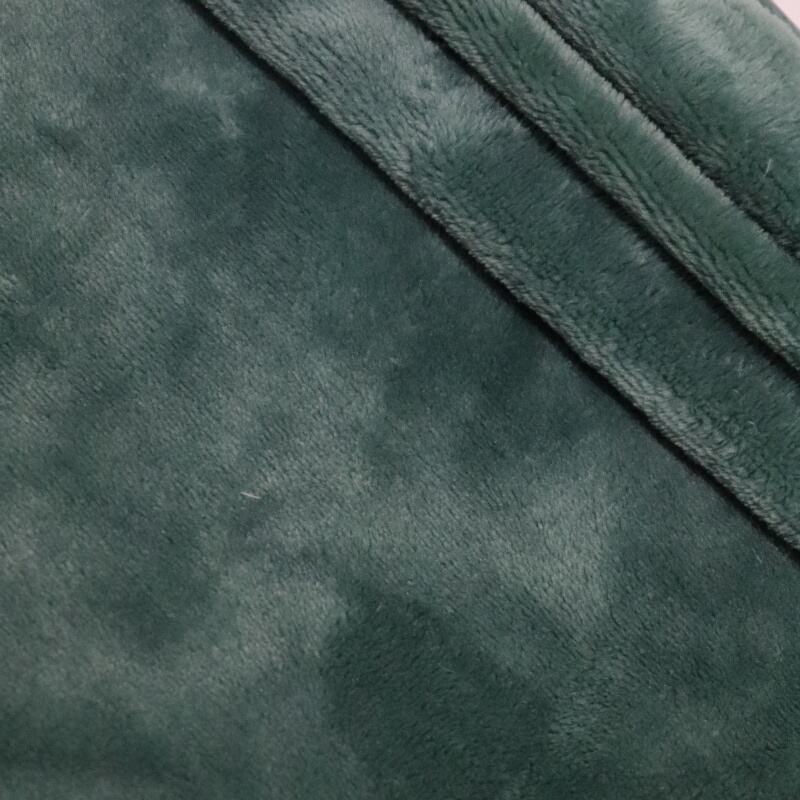

Here are some pictures for you to take a look!

---------Customization Service

---------Product Advantage

Green Dyeing Flannel Fleece Fabric Advantage:

1.Design: This Flannel Fabric with Fleece Face offers you different senses of softness.

2.Handfeeling: It is made of all-polyester. It has a good handfeeling with its ultra soft plush.

3.Application Scenarios:This flannel fabric is solid dyeing with green color. It is typical vintage style. It is very suitable for you to have it as gift blanket.

|

Material |

100% Polyester |

|

Details |

Care of skin. Soft and smooth feeling |

|

Size |

190X25X50CM |

|

Weight |

230GSM |

|

Package |

PVC Bag/PP Bag with insert card, ribbon...Also customized packing is available |

|

Delivery Time |

15 days for sample, about 35 days for mass production |

|

Payment Term |

T/T and L/C, FOB Ningbo or FOB Shanghai |

|

Cushion Case Certification |

OEKO, BSCI, GRS, GOTS |

--------- FAQ

1. Could l get a sample before order? Sample lead time?

We can offer free available samples for your evaluation, Sample lead time 5-7 days.

2. What is your Minimum quantity ?

For normal products, 500pcs/color for one style. lf you can not reach our minimum quantity, pleasecontact with our sales.

3.Are you a manufacturer or trading company?

We are manufacturer, not long can we offer best quality and lowest price, but can offer the warmestand the most professional service.

4. What types of packaging do you normally use forthis product?

For the package, our usual package is single Opp bag, pvc bag, custom gifts box and so on. We can print your custom logo on the package for free.

5. Can we add our logo to the productions? Could we have custom label?

We can add your custom logo on productions, Custom label is OK for us.

6. How long to deliver the products?

The exact delivery date according to your style and quantity, Usually within 30 work days after the deposite. lf you choose the items which we have stock ,we can deliver in 3 days.

--------- EDITEX

Why choose us?

Since our establishment in 1997, EDITEX has been committed to the manufacture of textile fabrics, and we are proficient in the process of fabric. We are trying our best to give customers the perfect service and products that customers feel satisfied. One product is the painstaking effort of both of us. You can trust us and give us an opportunity to show the best results.

Green Dyeing Flannel Fleece Fabric

Introduction to Green Dyeing Techniques

In recent years, sustainability and environmental consciousness have penetrated various sectors, including the textile industry. Green dyeing techniques are at the forefront of this transformation, especially when it comes to synthetic and blended fabrics like flannel fleece. Flannel fleece, known for its soft texture and warmth, is a popular fabric in various applications ranging from clothing to home textiles. This article explores the methods, benefits, and future prospects of green dyeing flannel fleece fabric, cogently showing how eco-friendly practices are revolutionizing this segment of the textile industry.

What is Flannel Fleece Fabric?

Flannel fleece is a type of fabric that originated as a blend of various synthetic fibers, primarily polyester. Known for its exceptional softness and warmth, it has found widespread usage in making blankets, pajamas, and even certain types of outdoor gear. The fabric features a brushed surface, which gives it its characteristic softness and insulating properties. Traditionally, the dyeing process for flannel fleece involved various chemical dyes and substantial water usage, contributing significantly to environmental pollution. This has triggered a quest for greener alternatives, pushing textile manufacturers to adopt sustainable dyeing techniques.

Sustainable Dyeing Methods

There are several innovative methods that manufacturers are adopting to dye flannel fleece fabric using environmentally friendly practices. One prominent technique is the use of natural dyes derived from plants and minerals. Unlike synthetic dyes, these natural dyes do not contain harmful chemicals and are biodegradable. For instance, indigo, derived from the indigo plant, and madder, obtained from the roots of the madder plant, provide vibrant colors without the environmental footprint traditionally associated with synthetic dyes.

Another groundbreaking method is low-impact dyeing, which involves multiple strategies to minimize waste and pollution. These include using closed-loop systems to recycle water and low-toxicity dyes that require lower energy consumption. In addition to natural dyes, low-impact synthetic dyes that adhere to stricter safety and environmental standards are also viable options.

Technological Innovations

Advancements in dyeing technologies have also given rise to innovative techniques that reduce the environmental impact of dyeing flannel fleece fabric. Digital printing, for example, is a newer method that directly applies dye to the fabric using specialized printers. This technique not only results in less waste but also allows for precise dye application, ensuring that no excess dye is washed away. Another modern approach is supercritical CO2 dyeing, which uses carbon dioxide in a supercritical state as a solvent for dyes. This method eliminates the need for water entirely and significantly reduces energy consumption.

Automation and artificial intelligence further contribute to sustainable practices by optimizing the amounts of dyes and auxiliary chemicals needed, in turn, reducing waste and emissions. Many factories are integrating AI-driven systems to monitor dyeing processes in real-time, making adjustments as needed to maximize efficiency and reduce environmental impact.